The new Update location module is here!

We've just launched the new Update location interface!

We've just launched the new Update location interface!

Good news! We have finally released the long-awaited feature: copy-and-paste tools within and between different tool lists!

Demonstrated below:

We’ve updated the way you sign in to the platform to make it easier — and give you more control.

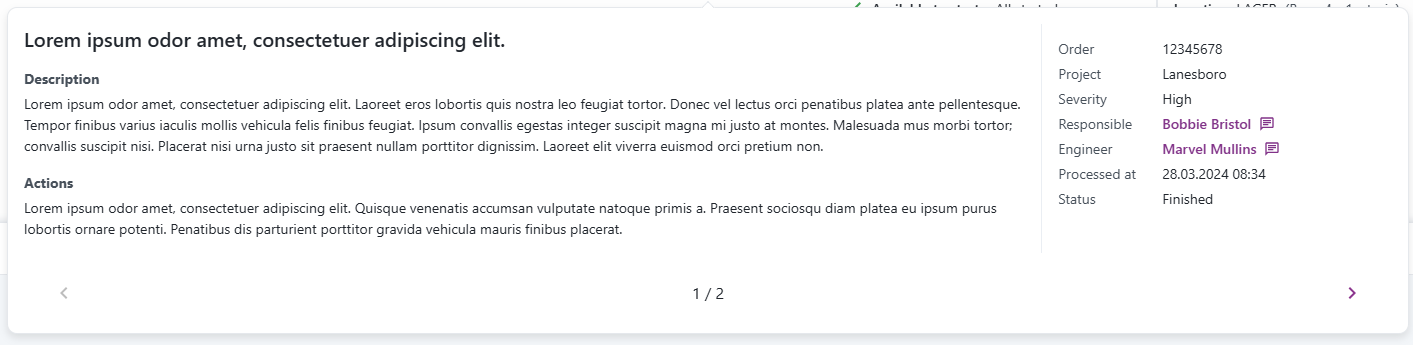

Operation and order details now include a link to engineering change orders for the part being produced. To show the information, use the ECO action button if it is displayed:

The information shown includes the description, actions and other information about the change order:

If the part has more than one engineering change order, use the < and > buttons at the bottom to scroll through them.

We have now launched the widgets Engage Schedule and Engage Order for Ignos Workspace!

We have now launched the Move bookings widget for Ignos Workspace. The widget displays the My bookings list and includes a built-in tracking function!

This widget presents both active and completed bookings. Users can cancel active bookings and print labels for both active and completed bookings. Clicking the order number allows users to track the order, and manual tracking is also possible by entering details in the tracking box.

Here's a quick demo:

During the last few weeks, we've released several updates for Pulse!

Below is a summary of what's new.

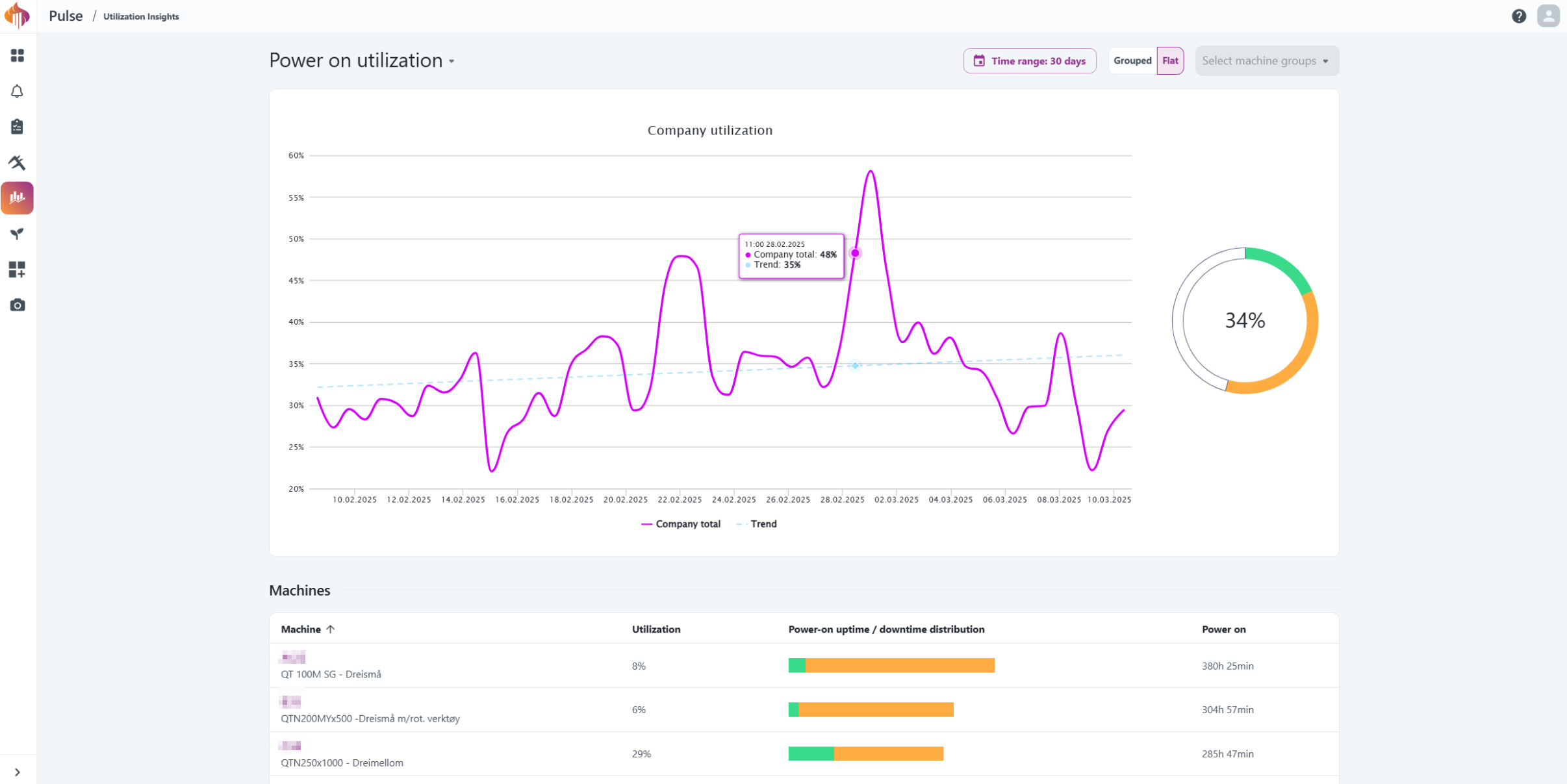

📈 New: A new surface for Utilization Insights is now available!

The new surface provides better visibility into utilization trends.

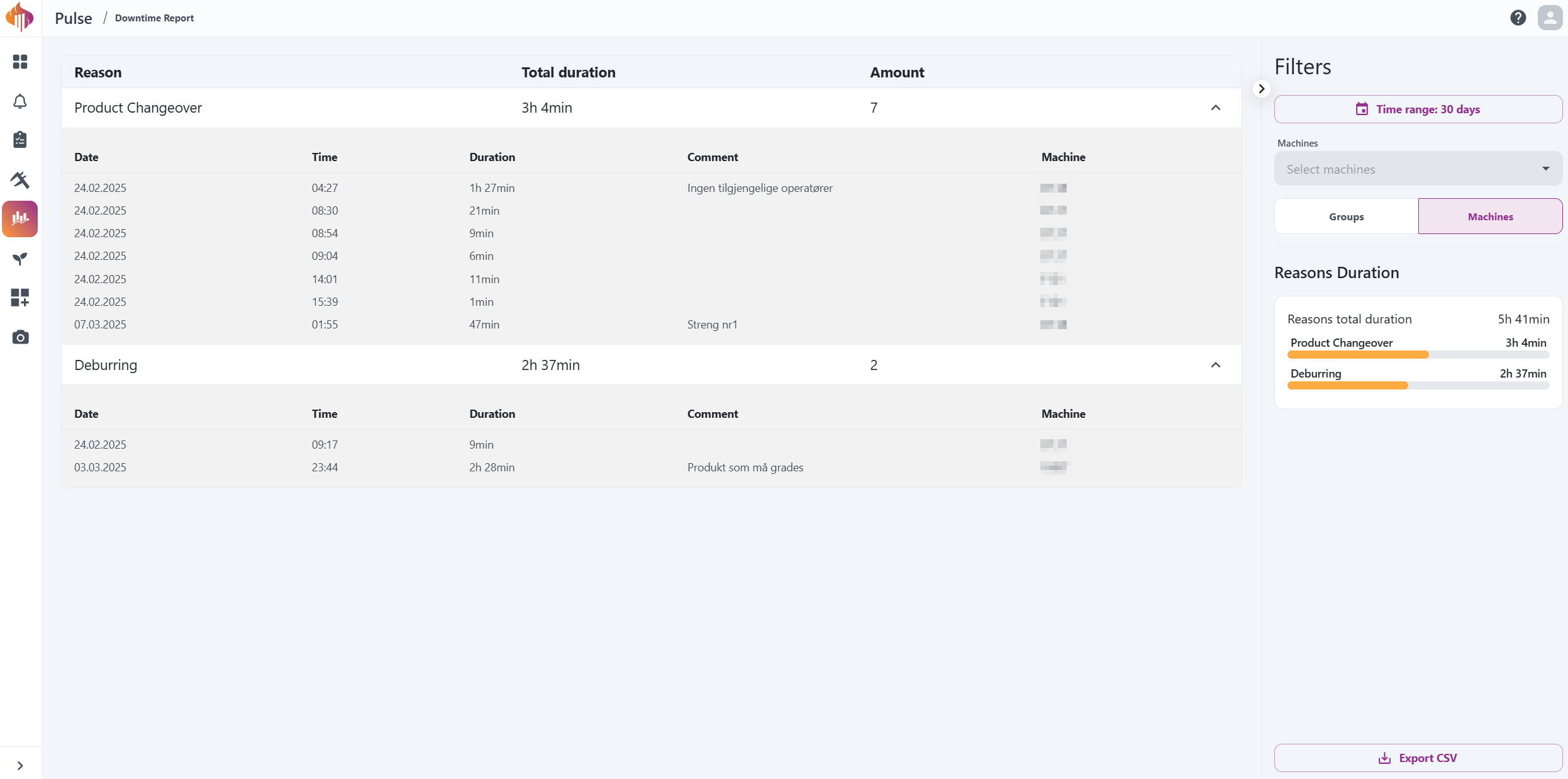

We've introduced two ways to report downtime reasons:

The Downtime Report gives deeper insights into the duration of all reported downtime reasons.

Two new widgets are now available from Workspace:

- Pulse KPI Widget

- The Downtime Reason reporting widget mentioned above

These updates have now been live for a couple of weeks! Try them out if you haven't already and let us know what you think!

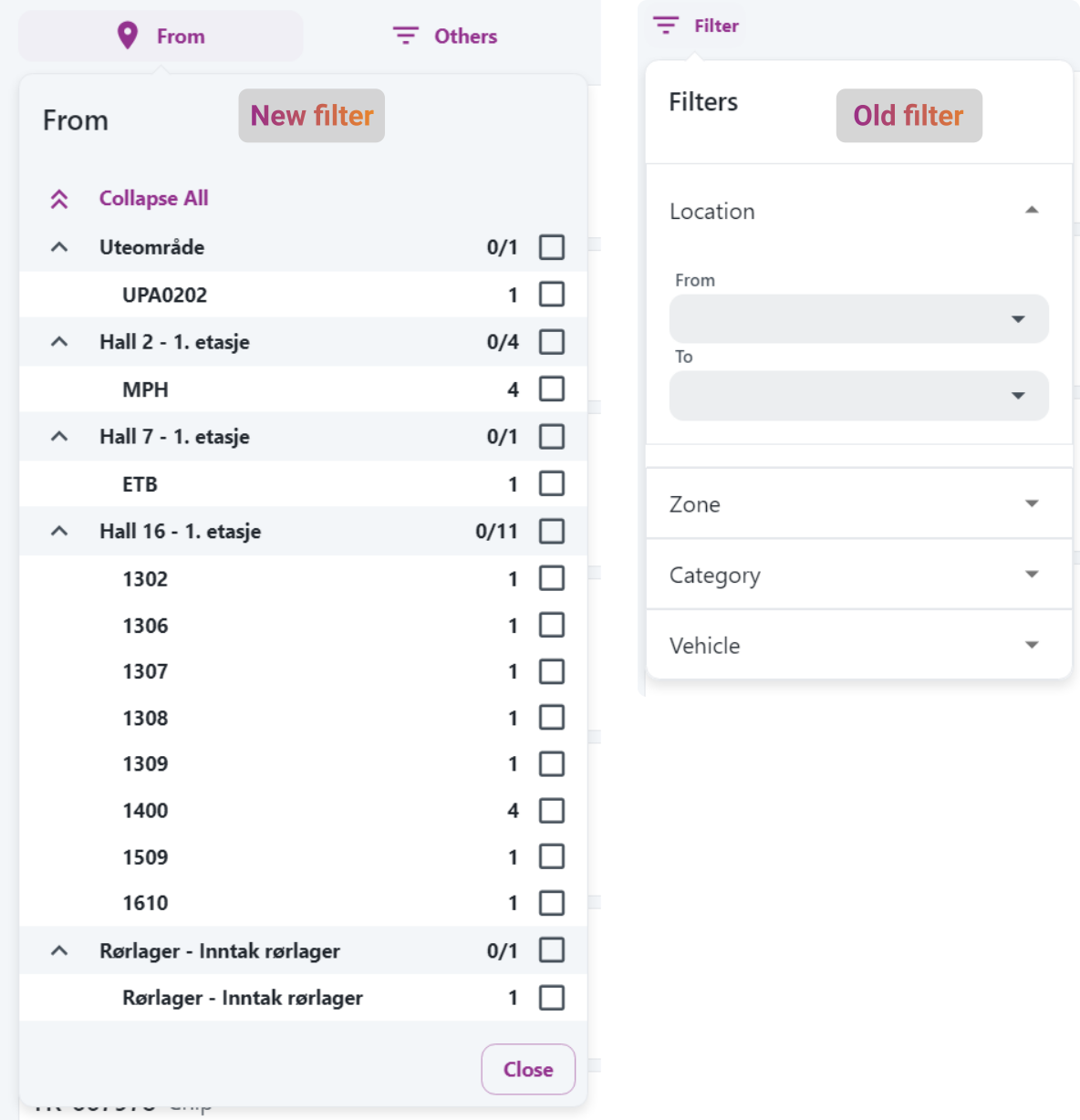

We’re excited to introduce a new, improved filter in the Driver interface!

This updated filter is designed to be more user-friendly, making it easier to see which zones have jobs, and apply filters accordingly.

Comparison of the new filter vs the old one:

As you can see, there are two key buttons, From and Others.

Here's a quick demo of how it works:

We're excited to share that we have been releasing several smaller updates the last week through the Move version 2 project.

One of the most requested features we'd like to highlight in this post, is the new Auto-fill From Location Setting.

This setting is tailored for stationary scanning setups.

It enables users to configure a default From location, which automatically pre-fills the From field during bookings.

The pre-filled value can still be cleared if necessary, allowing the field to operate as usual.

However, it will remain pre-filled until the setting is deactivated.

Here's a quick demo to show how it works:

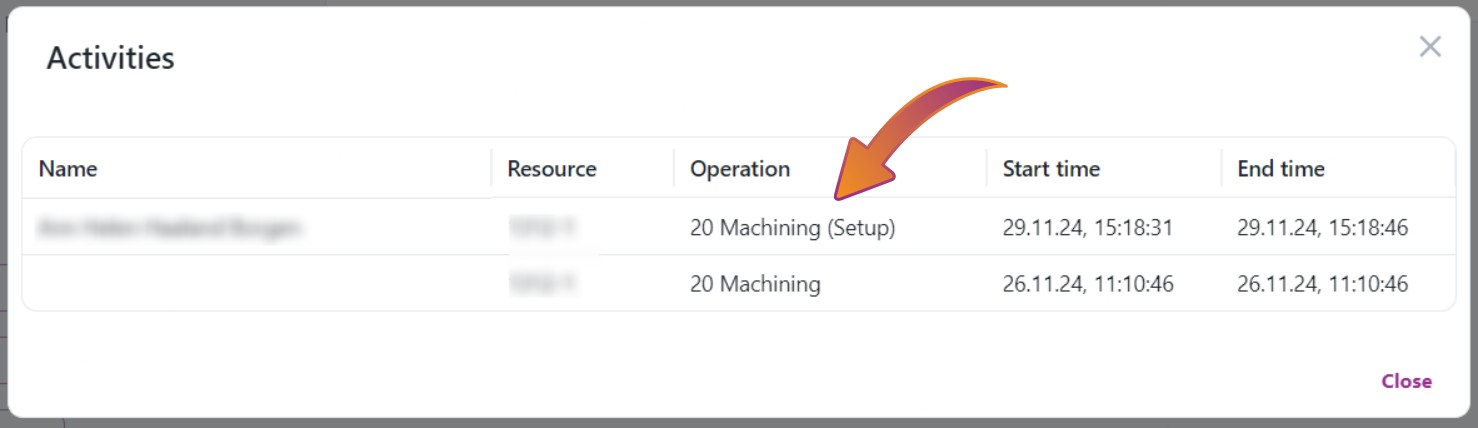

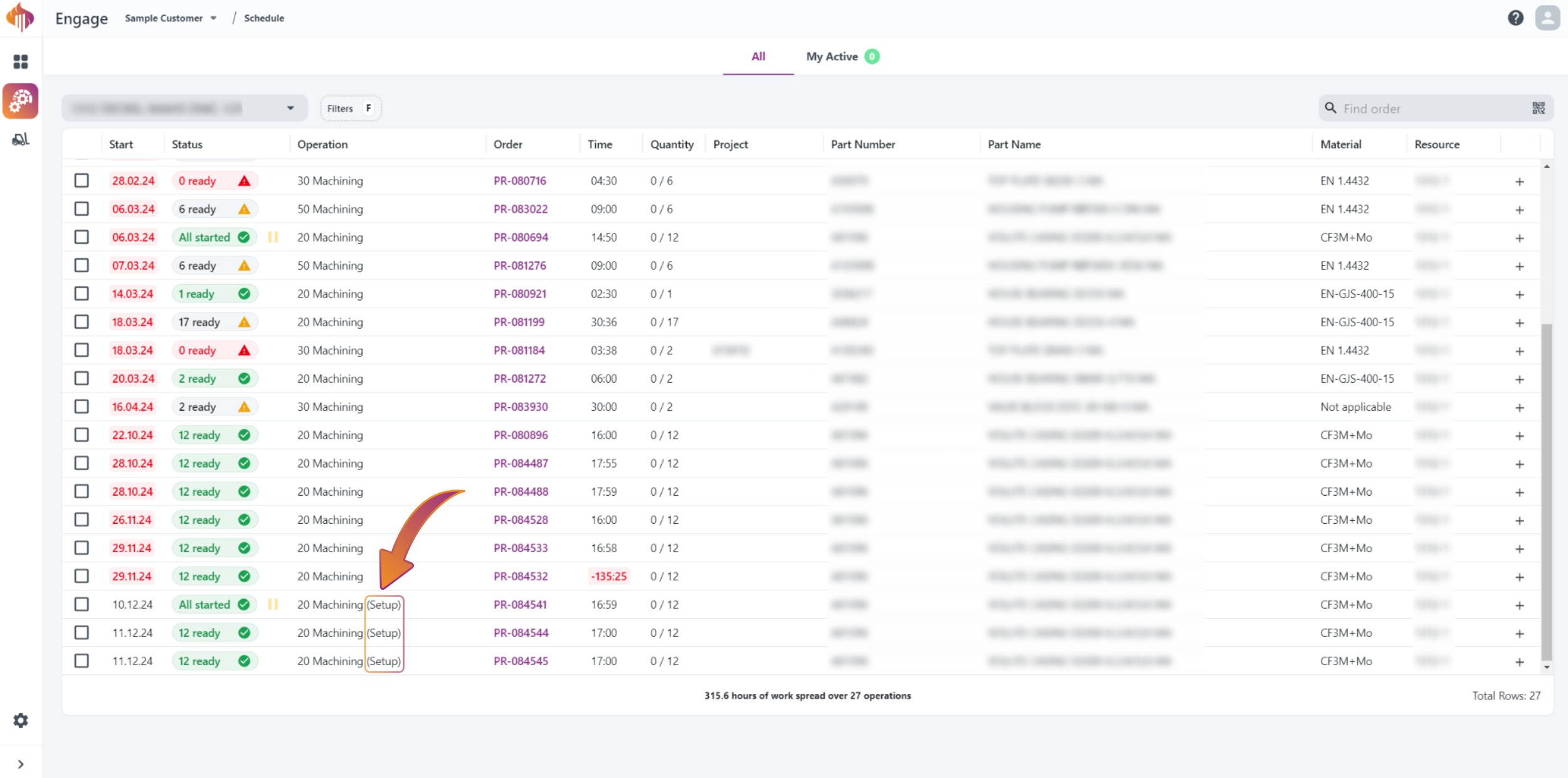

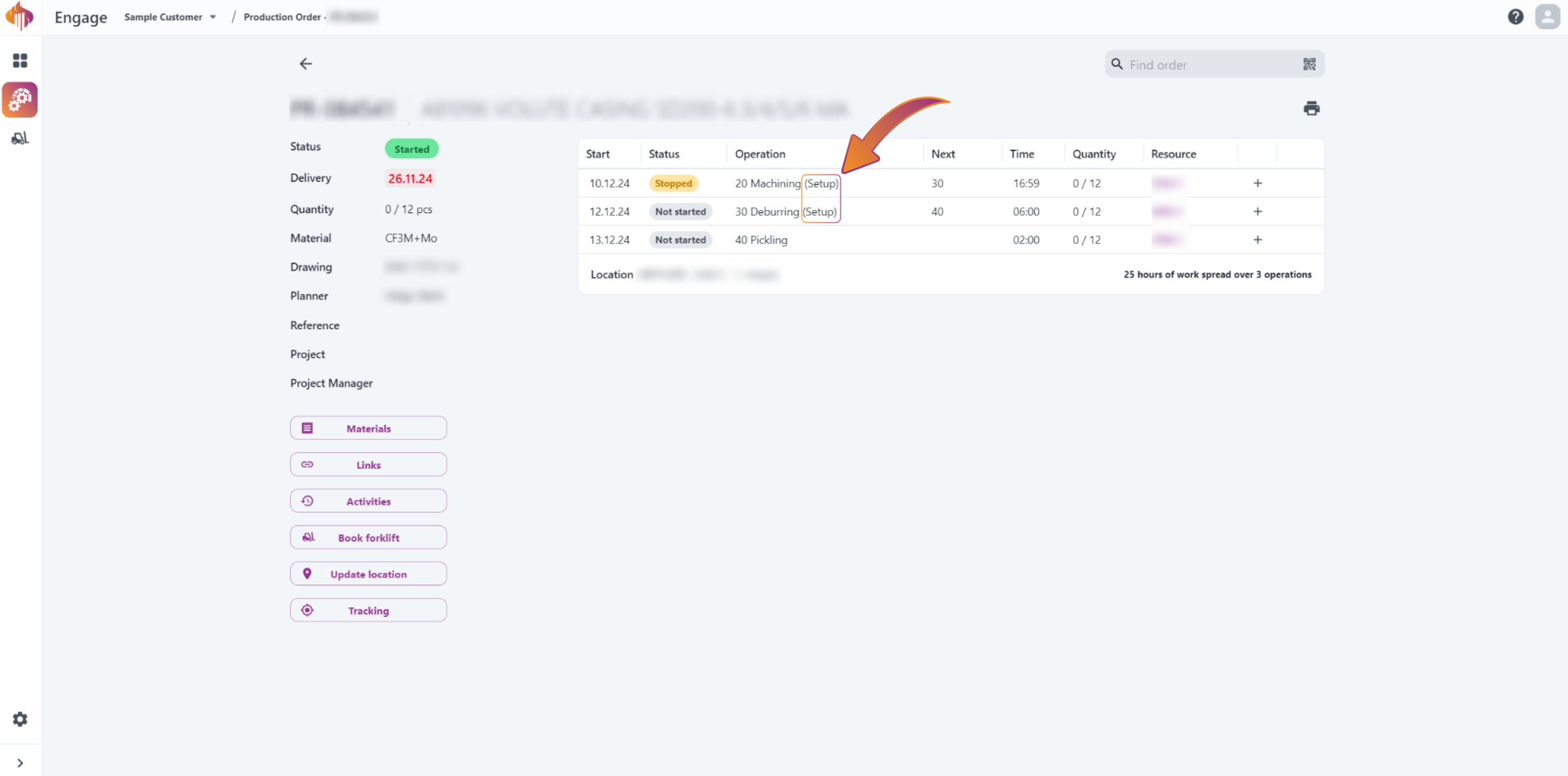

We have now enabled setup reporting in Engage!

If an operation includes planned setup time, it will appear as "(Setup)" in the Operation column.

From the machine schedule

From the machine schedule

From the order itself

From the order itself

Reported setup time will also be displayed in the Activities log.