New Pulse widget and updates to the Engage Order widget

We have now launched the Resource Current State widget and added improvements to the existing Engage Order widget.

We have now launched the Resource Current State widget and added improvements to the existing Engage Order widget.

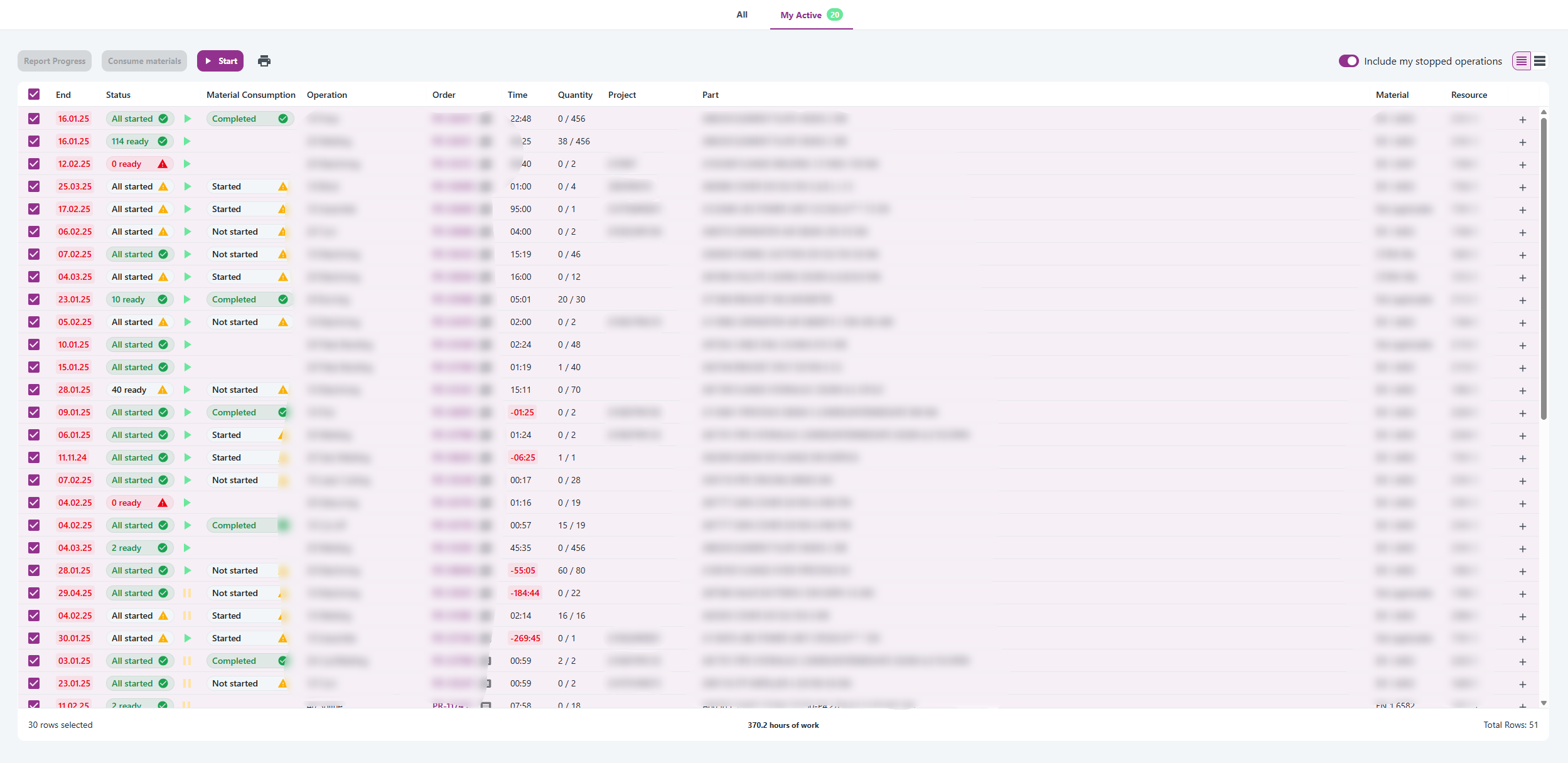

You can now select multiple operations at once in the My Active list! This makes it easier and faster to manage several tasks in one go. Use the "Select all" option to quickly select the first 30 items in your list and take action on them together.

Fresh improvements landed across Pulse and related apps. The time range picker is now consistent everywhere.

We have released an update to the Pulse app's Current States and Machine Timelines page summary, making it more insightful and relevant to your daily operations!

Top Downtime Reasons Visualization

Factory Summary Now Follows Filters

These changes make it easier to focus on the most relevant data and quickly identify trends or issues in your production environment.

Demo:

We have had a tracking function in Measuring Tools since the beginning. It has now been refreshed and extended with a useful new feature: last used by tracking.

This improvement is aimed at customers who do not use ERP integrations with Inspect. Previously, tracking was limited to showing the last known resource location, which depended entirely on ERP data.

![]()

1: Hover over the pin to view usage metadata.

2: Shows how many times the tool has been used. This value updates every 10 minutes, not instantly.

3: Location data is only available for customers with ERP integrations.

4: Displays the name of the last operator who used the tool (ℹ️ hover over the name to see the timestamp).

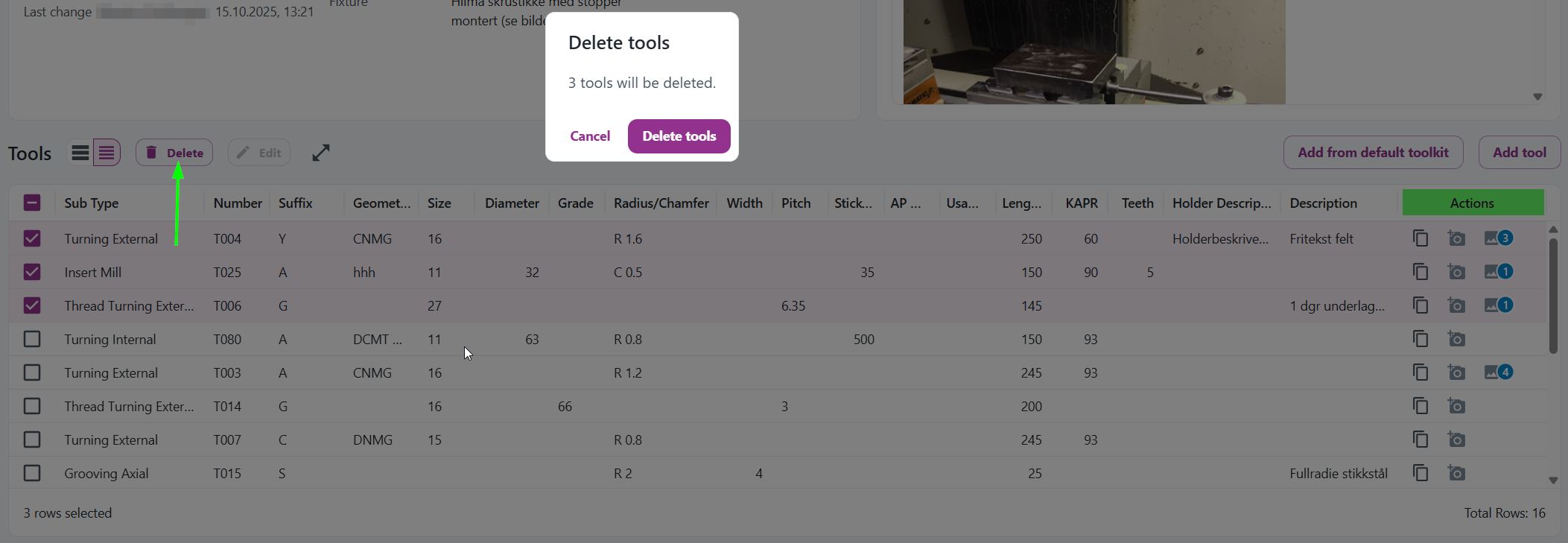

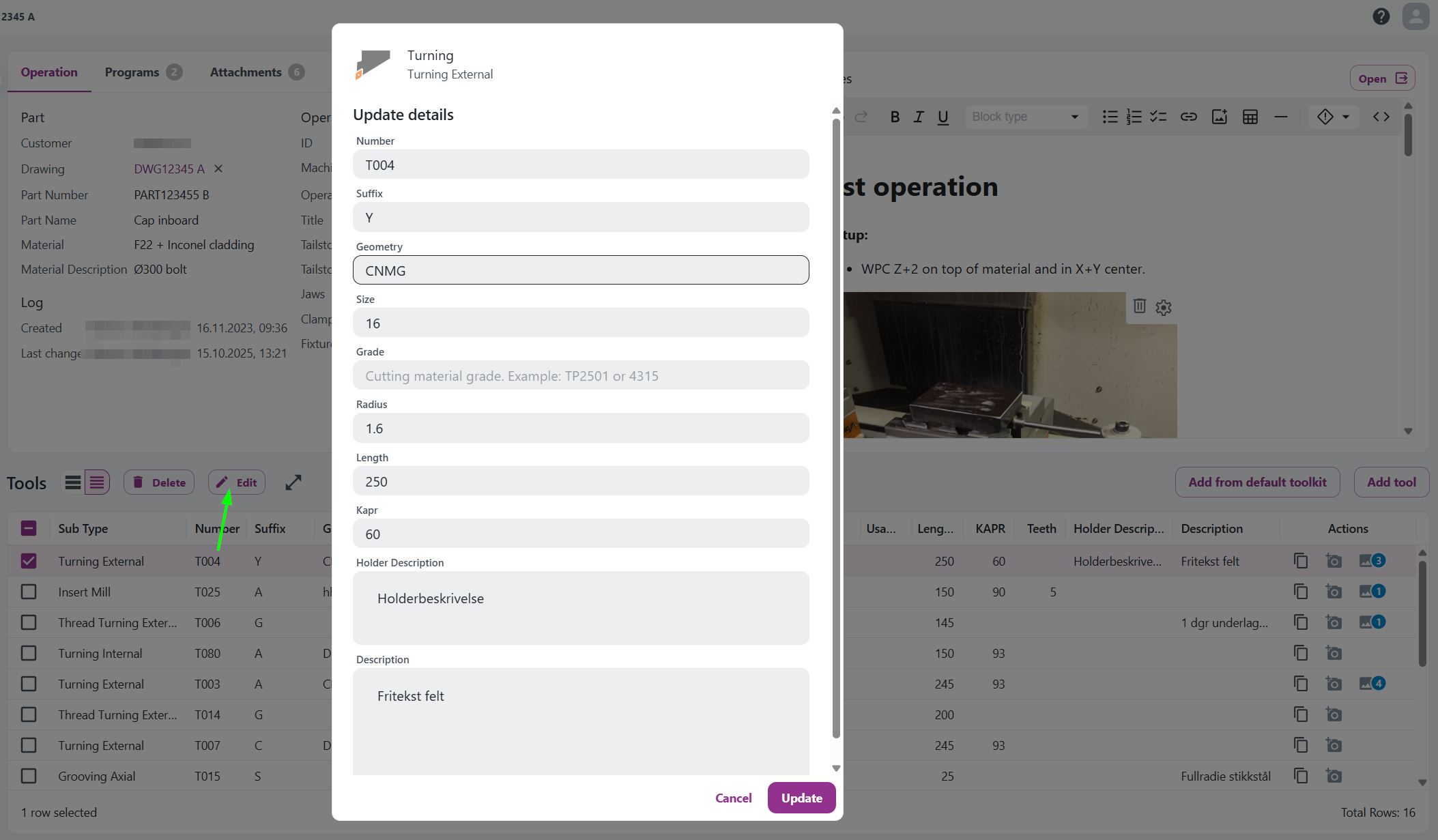

You can now multi-select tools in the Compact density view to delete several at once.

It’s also possible to open the Edit dialog instead of editing directly in the table.

The Edit dialog is available only when a single tool is selected.

Notice that the Delete button in the actions column has been removed. Use the new Delete button instead.

Notice that the Delete button in the actions column has been removed. Use the new Delete button instead.

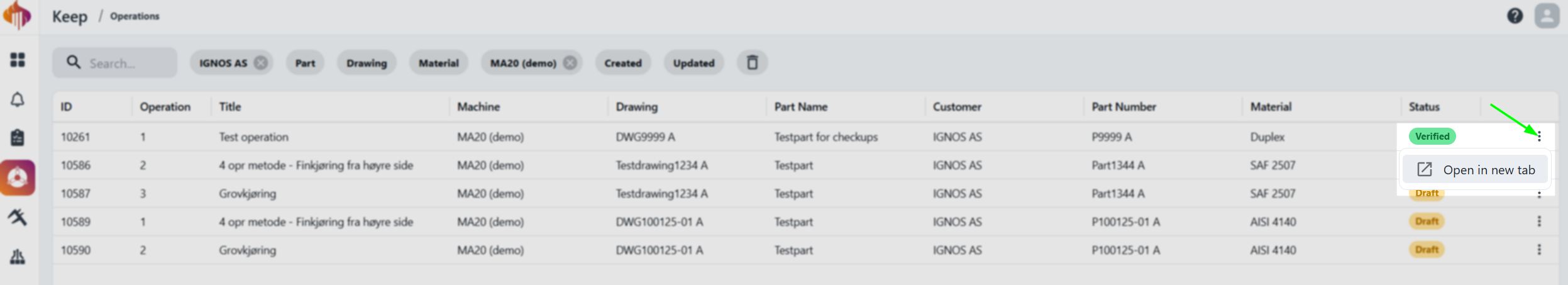

You’ll soon be able to open an operation in a new browser tab.

You’ll soon be able to open an operation in a new browser tab.

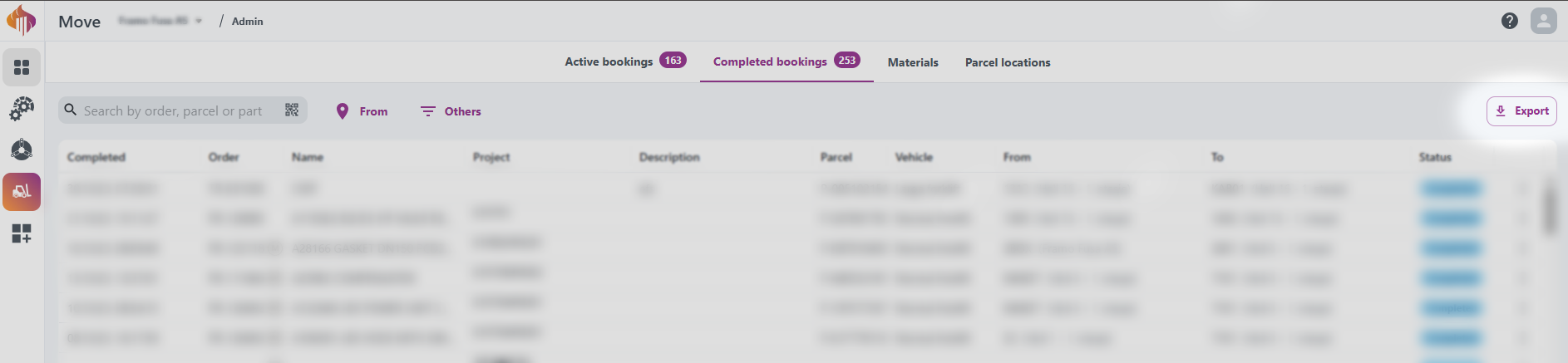

We're happy to introduce a new Export button in Move Admin! You can now easily export data from the following tabs:

Available export options include:

All exports are provided as JSON files for easy integration and analysis.

Here’s how it looks in the UI:

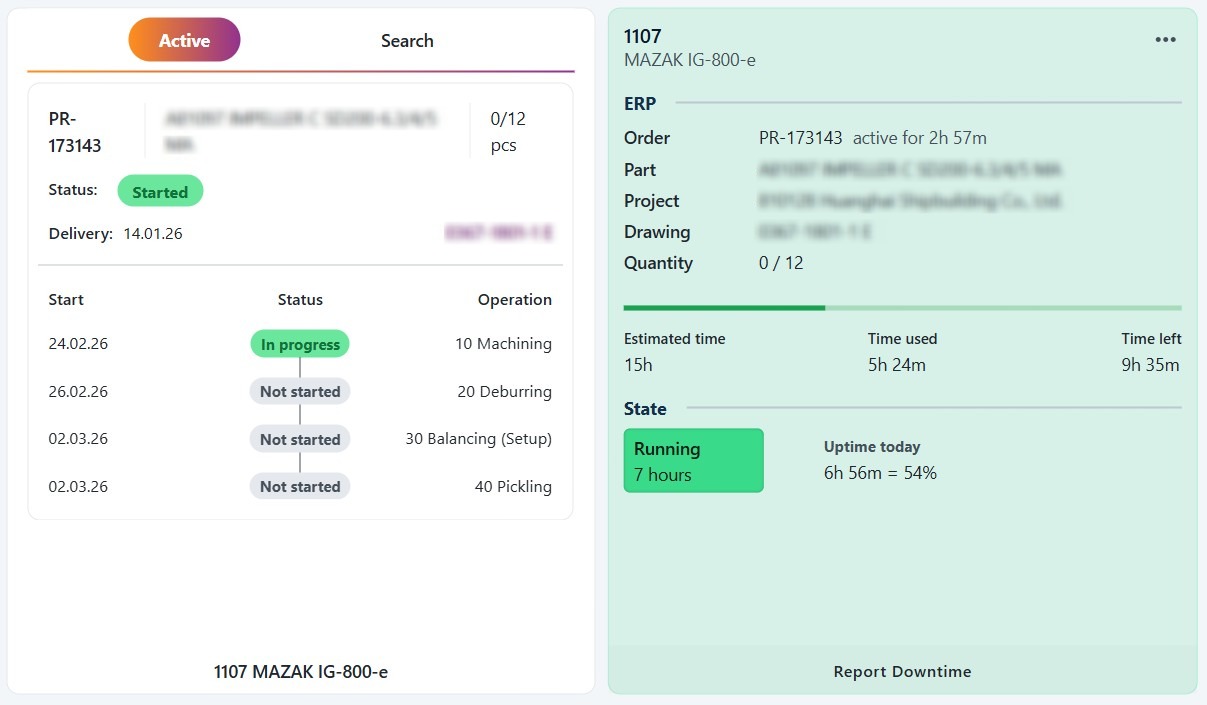

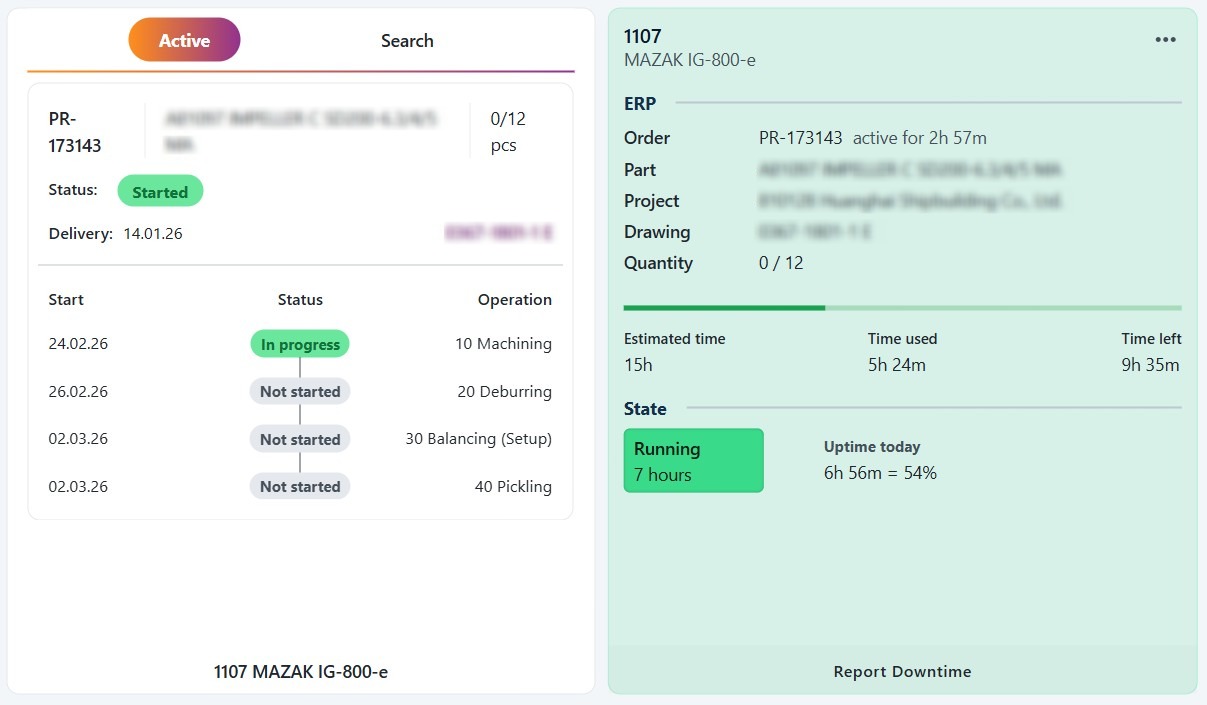

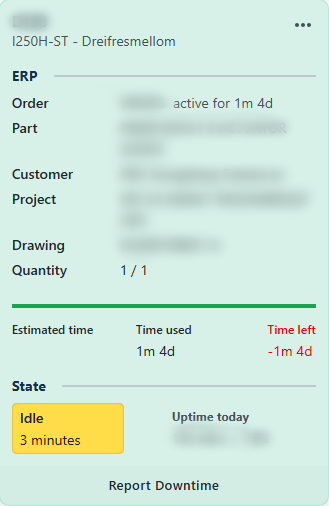

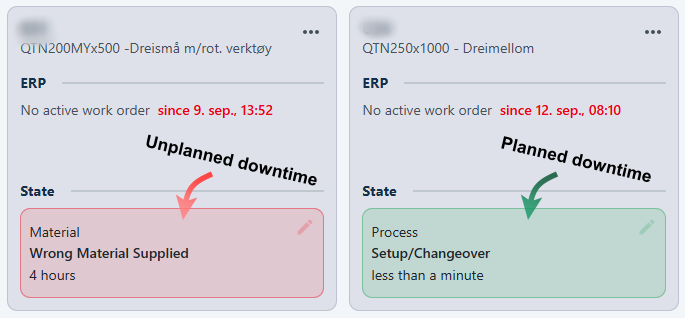

We have made it even easier to report and notice active Downtime Reasons in Machine States!

The resource card on the Machine States overview now has a dedicated Report Downtime button at the bottom. This makes it possible to report downtime for all resources. By clicking this button, you can start reporting downtime reasons just like in our report downtime widget in Workspace.

Here is a demo:

Resources that have active downtime reports will display a marker.

You can easily end or edit active downtime reporting by clicking the downtime report marker and pressing the stop button or checking/unchecking the "End downtime reporting when the machine state changes" option.

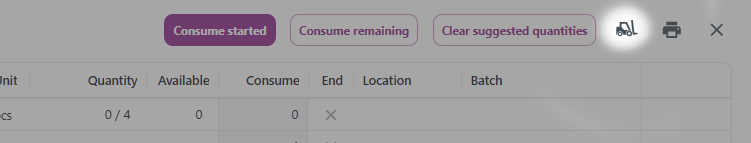

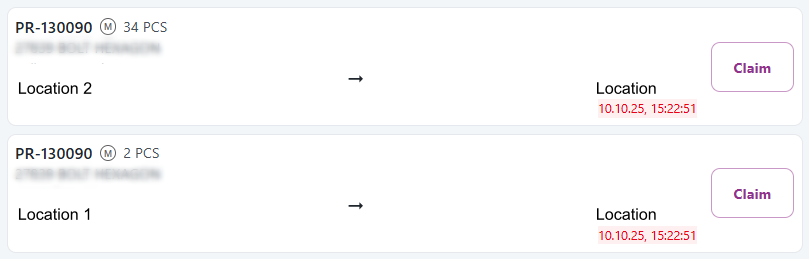

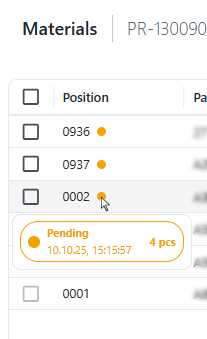

We are happy to introduce a new type of booking for our Move and Engage users: Material Booking! Now you can make a Move booking for material lines in Engage from the Materials and Consume Materials dialogs.

Material lines with available quantity are now selectable and can be booked by using the booking button in the top corner.

Material lines with available quantity are now selectable and can be booked by using the booking button in the top corner.

Output in Move

Material bookings are marked with an M throughout Move. The part information and quantity follows the material line and not the production order. A new table containing material bookings is added for related production orders in tracking.

Output in Driver.

Output in Driver.

![]() Output in Tracking

Output in Tracking

Material lines with bookings in status complete, pending, or in progress get a booking status marker. Hovering over this will give more information about the booking.

Example shows material lines with active bookings in status Pending.

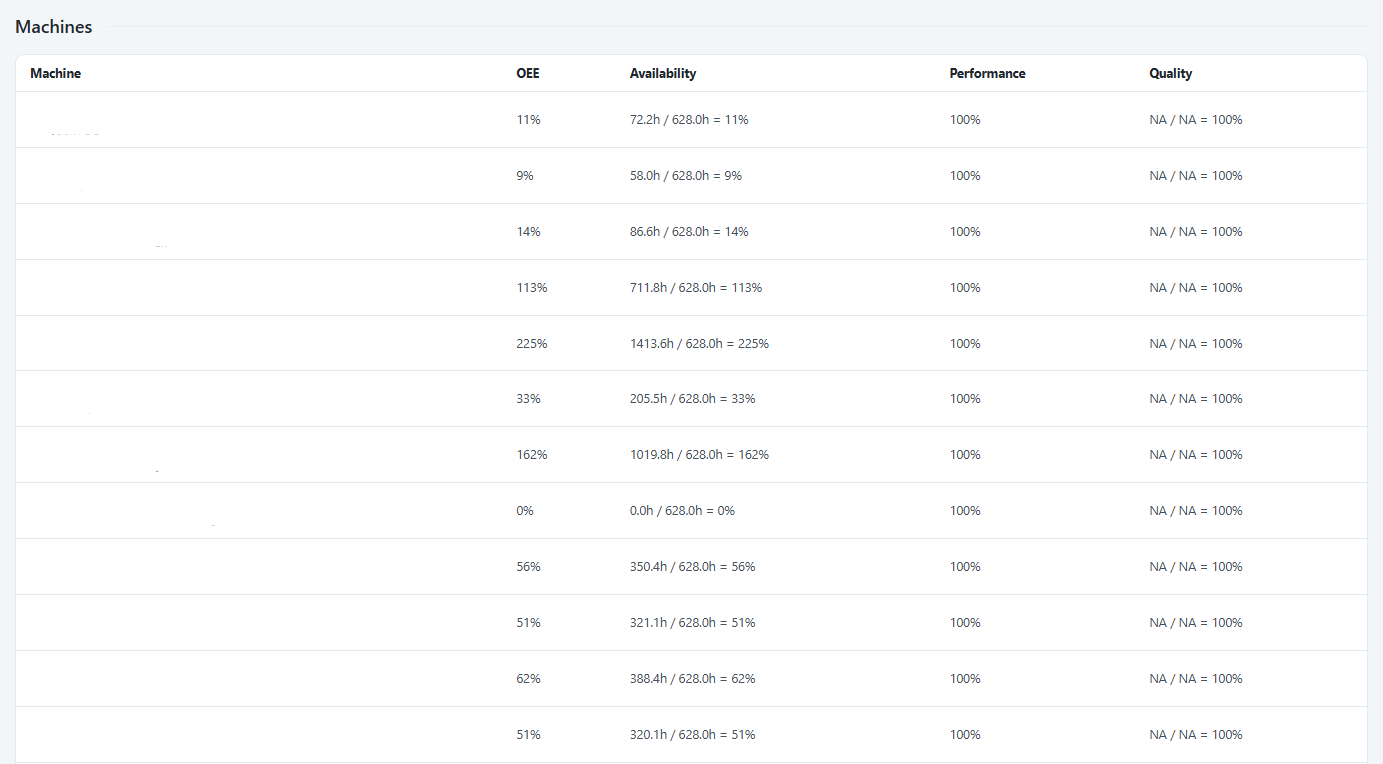

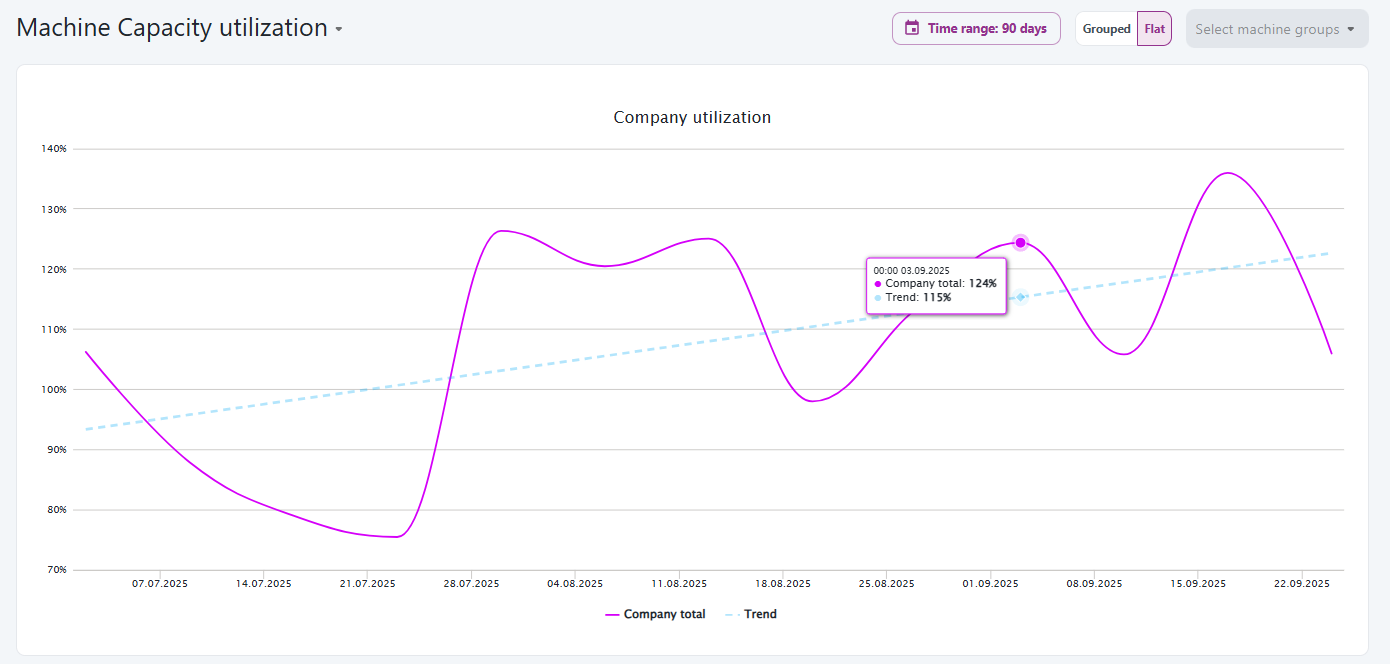

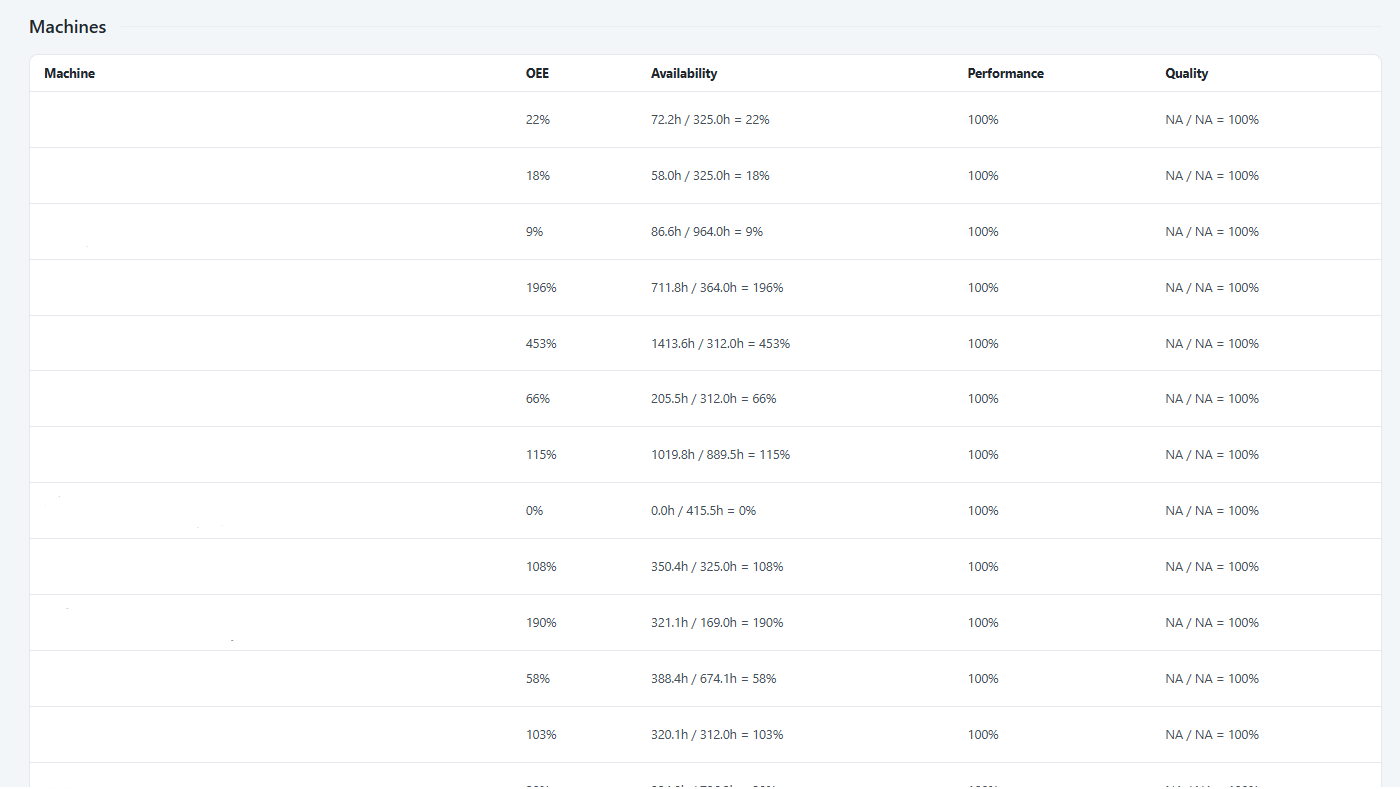

We’ve expanded Pulse with two new utilization methods:

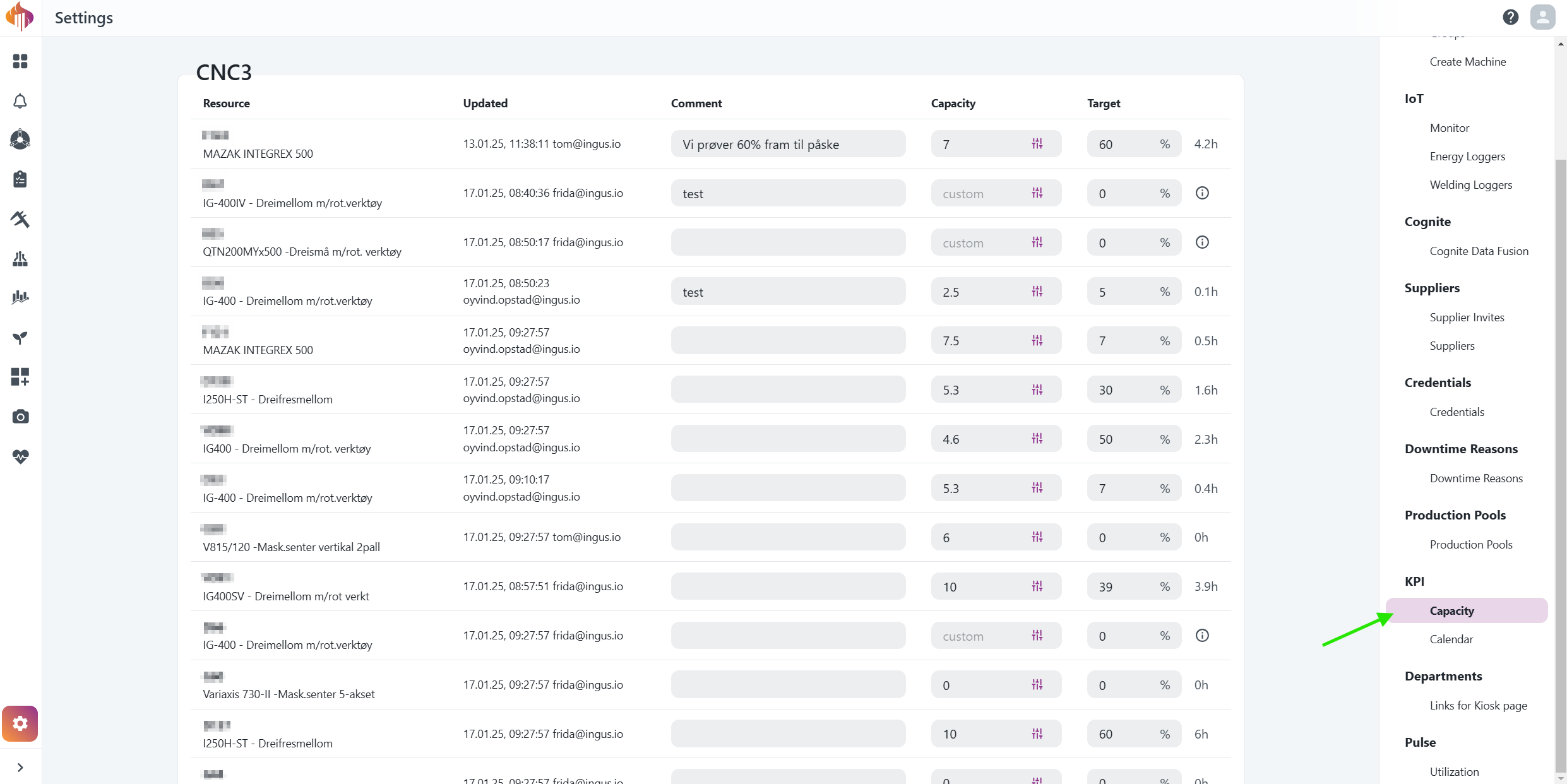

Machine Capacity utilization calculates how effectively a machine is used compared to its planned daily capacity.

Admins can dynamically configure the daily capacity for each machine.

For example:

If a machine has its Monday capacity set to 8 hours, and its uptime is 4 hours, the utilization will be 50%.

In systems where Performance and Quality values are available, the OEE calculation will include them. When these values are not provided, they are automatically set to 100%, meaning OEE effectively reflects Availability.

💡 Admin Tip:

Be careful when assigning very low capacity values (for example, 0.1 h) to weekends or non-production days. If the machine runs even briefly on those days, utilization can spike to unrealistic levels (thousands of %). Set capacity to 0 h for days with no planned production to avoid distorted results.

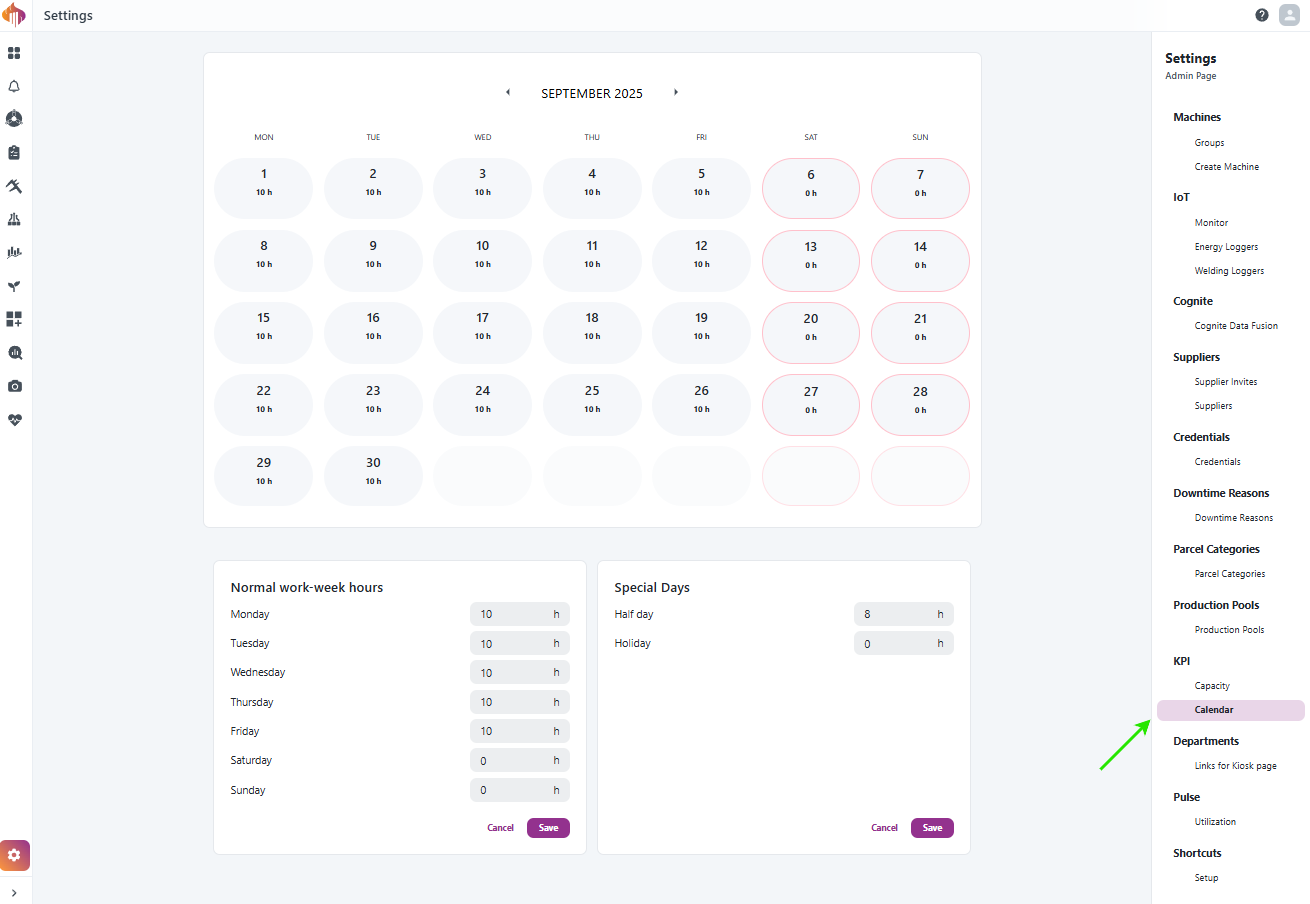

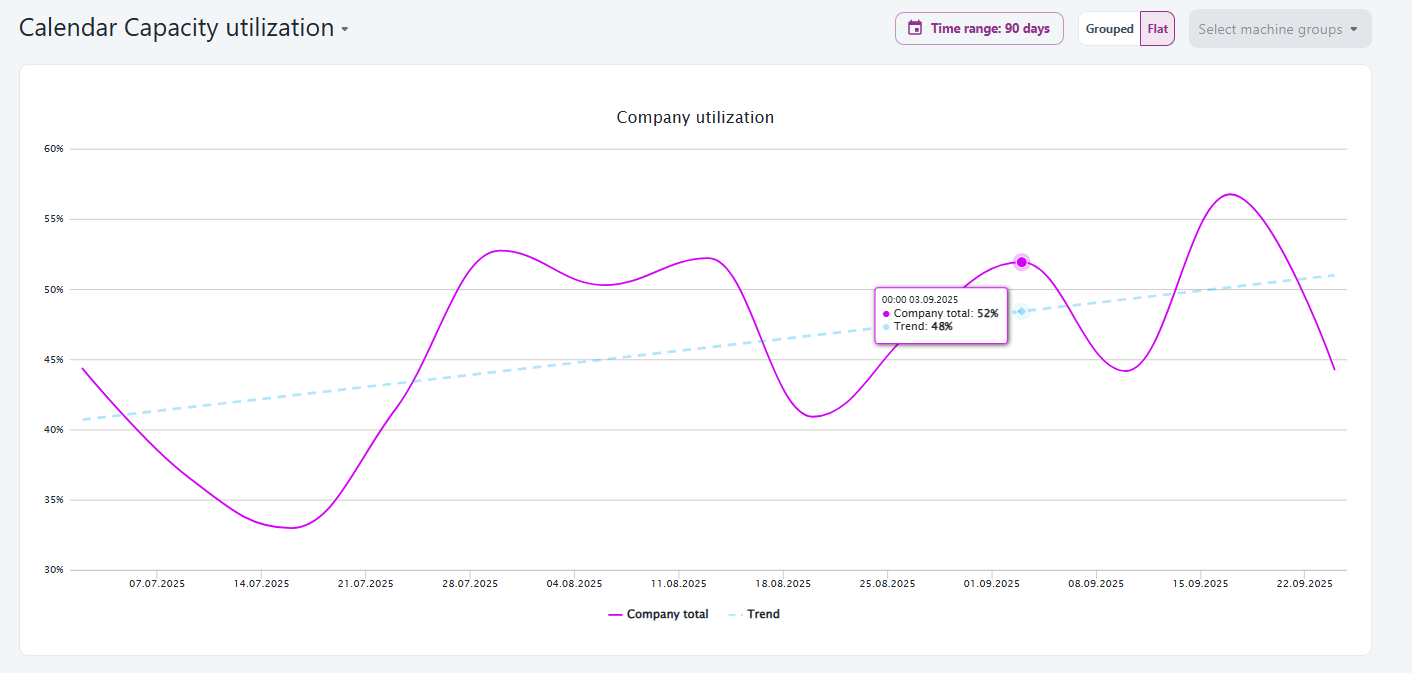

Calendar Capacity utilization calculates how effectively a machine is used compared to the company’s planned calendar capacity.

Admins can dynamically configure the calendar capacity.

Just like with OEE, in systems where Performance and Quality values are available, the OOE calculation will include them. When these values are not provided, they are automatically set to 100%, meaning OEE effectively reflects Availability.